For the month of September, we are focussing on the talents and benefits of providing apprenticeship opportunities by asking our own apprentices their feedback on their experiences working within our teams.

Our first Spotlight is on Aidan Harrison, a Trainee Engineer studying at the University of Nottingham, who is doing a course in Civil Engineering with an Industrial Year MEng. This involves 5 years of education, with the 4th year being an Industrial year out. Aidan recently completed his summer work experience placement of 8 weeks at Moortown Group.

Read on to hear Aidan’s thoughts!

Why did you choose this vocation?

“I really liked Maths, Art and Sciences in school, so it seemed like a logical direction to take when I chose these as my A-Levels. I’m very interested in architecture and engineering, and these subjects blended well together”.

“I realised that by going down the Civil Engineering route it could offer a good balance between drawings and communications which would still be underpinned by maths. It appealed more when I heard that there was a great need for this role in the industry so I decided to pursue engineering opportunities”.

What has it been like working at Moortown Group?

“My Experience at Moortown has made me feel a valued member of an experienced team of estimators and quantity surveyors who have been exceptionally welcoming throughout my time at the company. Everyone has been very helpful and receptive; I have learnt a great deal about the construction industry all round, especially the nature of work within the subcontracting sector.

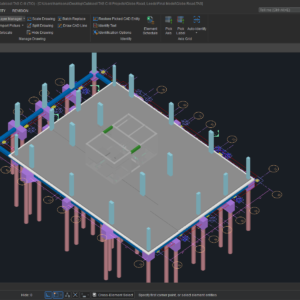

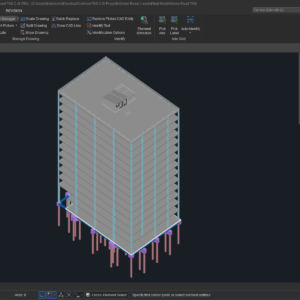

My technical knowledge of RC structures, including how to conduct accurate material and quantity take-off, has been improved considerably since I started work. I will return to University with some great industry experience and connections which will form the basis of my future career. I am impressed that I got to be so involved and actually contribute to the work needed, as opposed to shadowing somebody”.

What skills have you learnt?

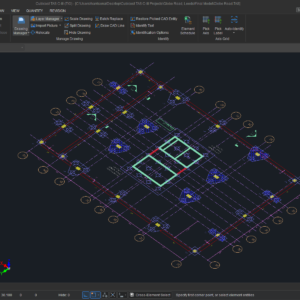

- Cubicost TAS C-III (Architectural and Structural) quantity take-off software

- Ability to interpret structural drawings provided by clients

- Technical knowledge of RC structures and groundworks

- Improved interpersonal communication and professional skills

What advice would you give to future students looking to get into this industry?

“Prospective students need to know if the opportunities in construction are ‘future proof’ to some degree, and that there is some level of stability in committing to a career in this industry. If construction companies are hoping to recruit young talent, it would be a big help to us students if these roles were advertised alongside a list of courses, so we could see clearly what aligned with what. This would be a massive help to see where the opportunities lay and how they fit into the ‘real’ working world”.

What did you like about our company?

“I became very aware early on that the majority of staff I was introduced to and met had been working there for many many years. People must stay for such a long time because they feel valued and enjoy the work culture here, and they see the potential in growing with a company that looks after them”.

This September, Aidan will return to University to complete his final year of study and we’re certain he will graduate with flying colours! We look forward to hearing from you again, all the best with your studies.