Transformative Employment Opportunities for Prison Leavers

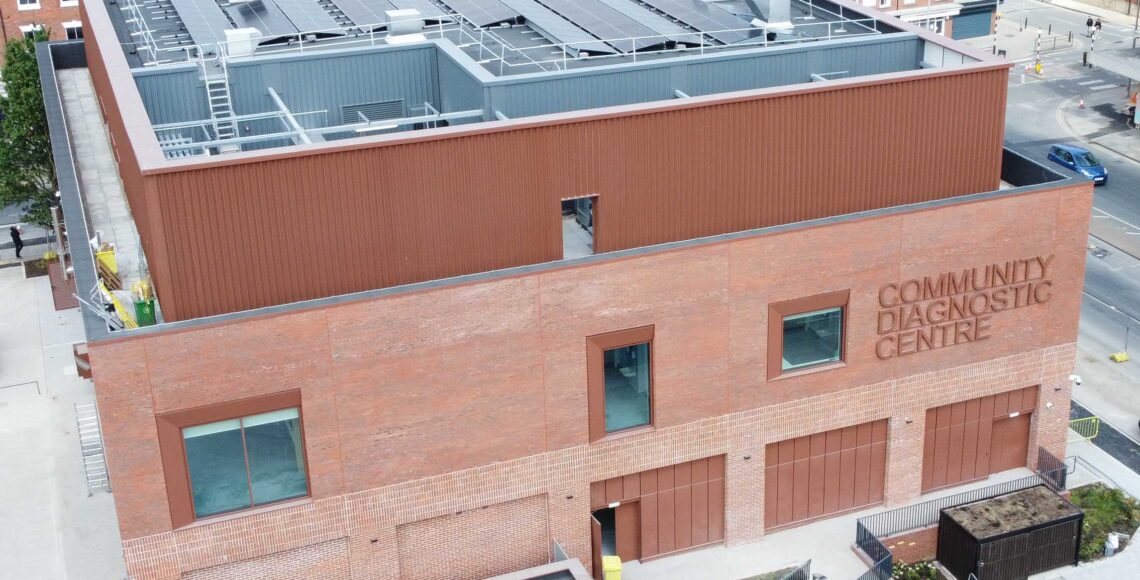

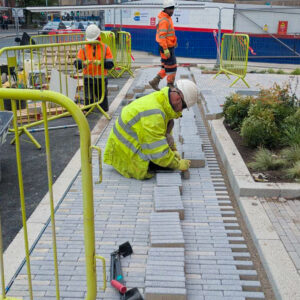

We are thrilled to have been part of Kier’s innovative ‘Making Ground programme,’ which focuses on engaging with prisons to offer training and job opportunities to prison leavers and those on temporary release. Since joining the HMP Millsike project in 2022, we’ve been committed to this rehabilitation effort by providing employability training.

Our Resourcing Manager participates in prison career fairs, connecting with potential candidates and facilitating interviews and job placements.

“In total, we have been able to support 12 people, which includes 3 prison leavers and 9 ROTLs. Hearing how well Andy has done is such an inspiring example of how opening doors to opportunities can deliver great results for everyone involved”

– Katy Chatterton, Resourcing Manager, Moortown Group

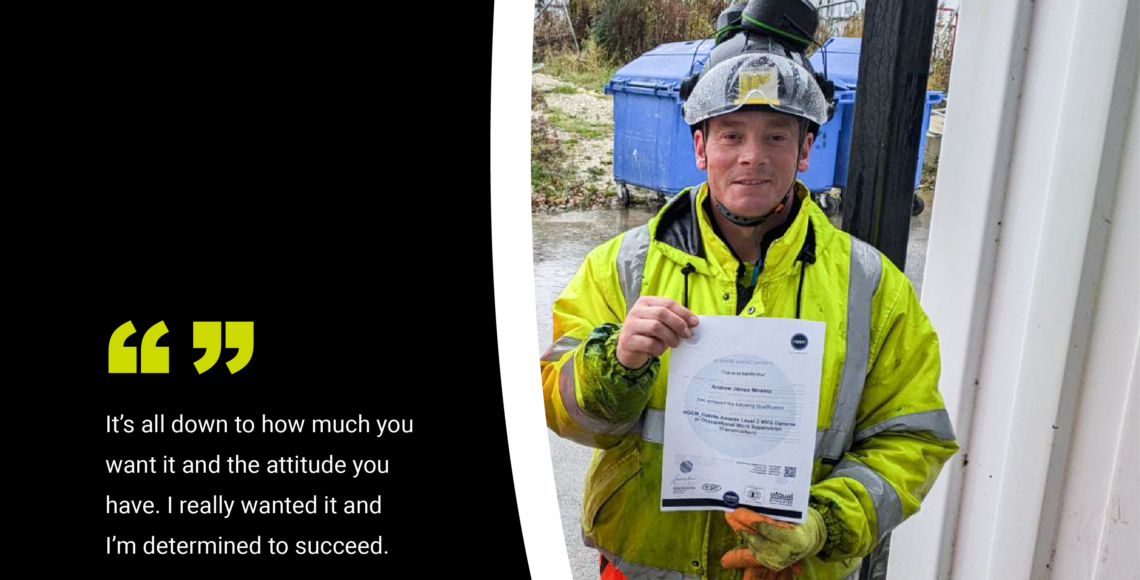

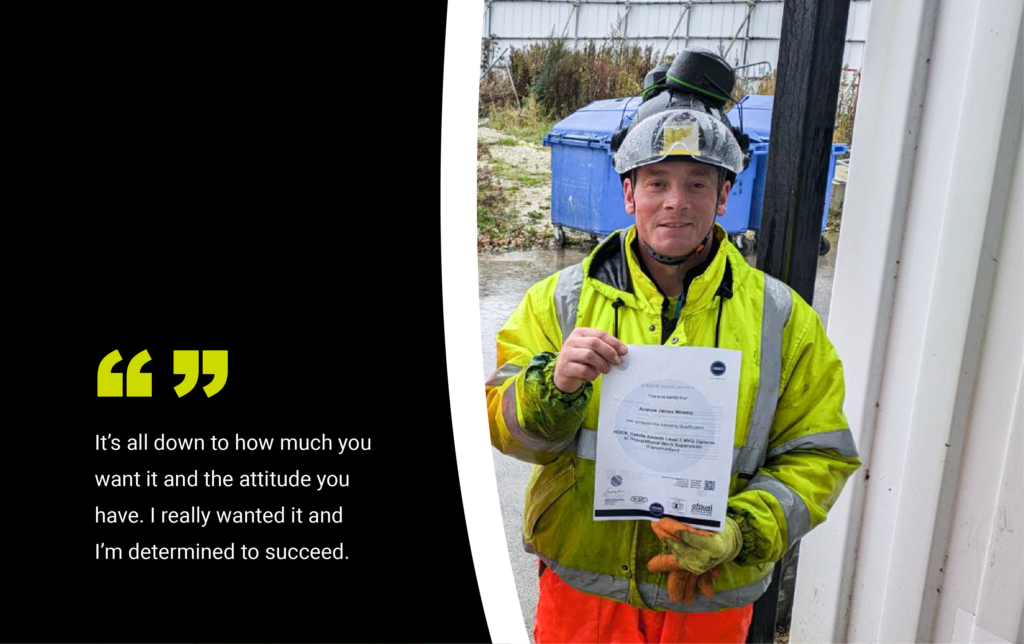

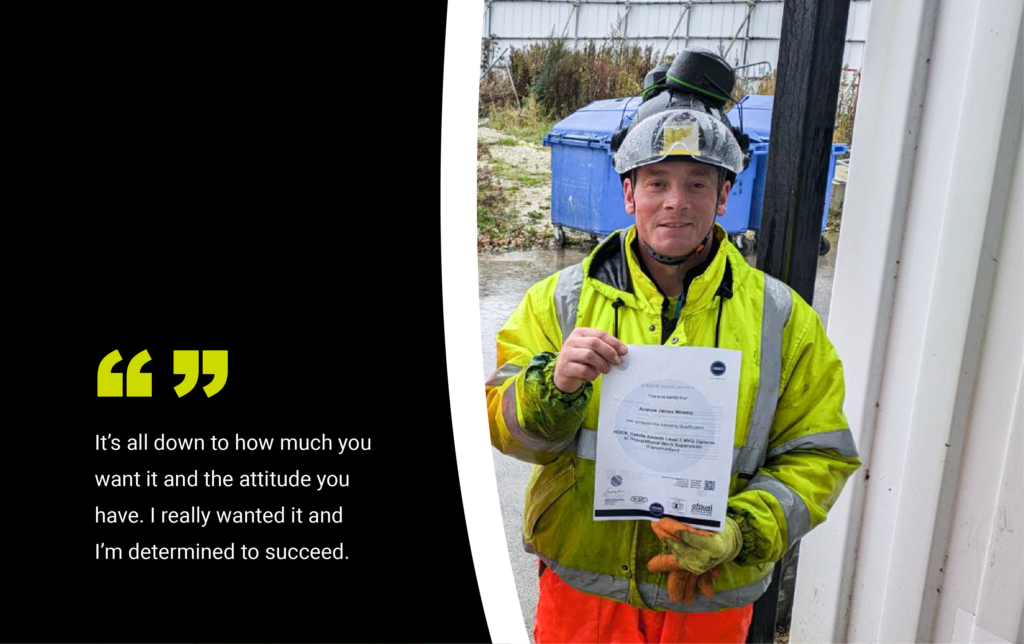

We caught up with Andy Minskip, a former prison leaver who has spent the last two years working on this site with our team. We felt it would be invaluable to hear his thoughts and reflect upon the whole process. Feedback is key to ensuring the right structure and support is in place for our people to succeed, and for those who continue to join us in the future.

Upon leaving prison, what were your thoughts about getting back into work?

I wanted to get back into work straight away. It’s the first proper job I’ve ever had. I was grateful for the opportunity and when Moortown rung me back, I immediately accepted their offer.

How did you hear about the opportunity available and how was it presented to you?

I attended a construction event at Hatfield Prison, where many companies promoted their current opportunities. I was keen to sign up with a construction related company.

Did you have any previous experience in construction?

None at all, just bits and bats helping others out in the past but no formal training of any kind.

What appealed or interested you about this opportunity?

I always liked the thought of hands-on work, getting stuck in and working outside.

Had you heard of any other prison leavers succeeding with other employment opportunities like this one and felt encouraged?

No, it’s the first time I’ve witnessed a prison hosting a careers event.

In those first few weeks and months, what was it like turning up to a new job on a new site to begin learning the ropes?

At first, I was a little overwhelmed, but I definitely felt very motivated. I was one of the first to arrive at this job and it can be a bit nerve-wracking because I expected a lot of people to judge me as one of the “prison lads”. Aside from this, I just turned up every day and got on with my work.

Andy’s qualified roles include: a labourer, a dumper driver, slinger and groundworker. He’s also achieved Supervisor level and obtained a Level 3 NVQ, along with successfully completing our Black Hat Training programme and acquiring his site supervision card (SSSTS ) and his site manager card (SMSTS).

Project Manager, Tommy Housten commented:

He’s been doing a Black Hat role which he’s been good at and progressed very quickly. We saw potential in him to take the lead and we put him forward. He’s the only one that’s achieved this with us.

How does that make you feel Andy?

It feels really good to hear they had faith in me.

Looking back two years ago, could you have imagined being in this position now?

No. Not at all. I can hardly believe it to be honest.

Most enjoyable parts?

Ducting, I love doing ducting. It was definitely something I enjoyed learning about. The site guys here told me it’s been a significant task on this project, and they’ve had several years of experience to compare it to. Next thing I’d like to do is learn about deep drainage.

Most difficult parts?

Learning time scales, programmes and targets. Getting things ready and prepped.

In your opinion, is there any reason in general not to succeed with an opportunity like this?

In my opinion, I’d say it’s all down to how much you want it and the attitude you have. I really wanted it and I’m determined to succeed.

How does the support impact your overall performance?

The support has helped fast track me to where I want to be. It might have taken me longer to get to this point without it. The encouragement makes me feel I can stick at it.

If any, what improvements would you suggest for the whole process?

Everything has worked well for me, there’s nothing more I would suggest.

What have you learnt about yourself from the whole experience?

That I can work, that I can live a normal lifestyle, and it’s definitely changed me. It was time to change because otherwise I’d end up back in prison for life or even end up dead. This was a big turning point.

What was life like before prison and your outlook on life?

I served just over four years. From a young age I didn’t care about life. It’s just what I did. But this opportunity has given me a huge amount of purpose back and it’s time to change and grow up. I needed to.

Tommy Housten, Project Manager, Moortown Group – What have you learnt from the experience?

The experience has left me more opened minded about the potential of rehabilitation. Whoever they are, they deserve a second chance. Some will graft and some won’t. You can see in the first week if they’re truly interested. With Andy, he wanted to be here and progress, to change his life and move on. It’s brilliant to see.

From day one we saw something extra in him, he had to report to me what he needed, we would plan ahead, he did his qualifications and took to it like a duck to water. He was easy to manage, his confidence grew week by week. He was never too proud to ask for help or afraid to raise a question if he wasn’t sure. He’s the most honest lad I’ve come across, he won’t try pull wool over your eyes, he’ll tell you as it is. If he makes a mistake, he puts his hand up. Can’t ask for more. He has the right mentality for the construction site environment and he’s going to do well.

It’s been a pleasure to support Andy and see him progress, emphasising further the importance of breaking the cycle of reoffending and providing those second chances that make a crucial difference. His success is testament to the impact of opening career doors, and we aim to continue with our commitment with rehabilitation opportunities with the hope it can reduce reoffending and help individuals reintegrate back into society successfully.

We are confident that Andy’s skills and dedication will lead him to further achievements and opportunities in the future. His contributions have been invaluable, and we look forward to seeing him on another site soon.

.

.