North East Project Recap

The start of the year saw several North East projects reach their full completion. Working predominantly in the Defence and Health sectors, we deployed a handful of various teams and kit to begin works on these sites.

Sunderland Magistrates Court

At three locations within the existing Magistrates Court building, we undertook basement infill concrete works. This meant there was restricted working room, and extra considerations were required when working in a live building environment.

- Value: £100k

- Duration: 6 weeks

- Client: Galliford Try

HMP Northumberland

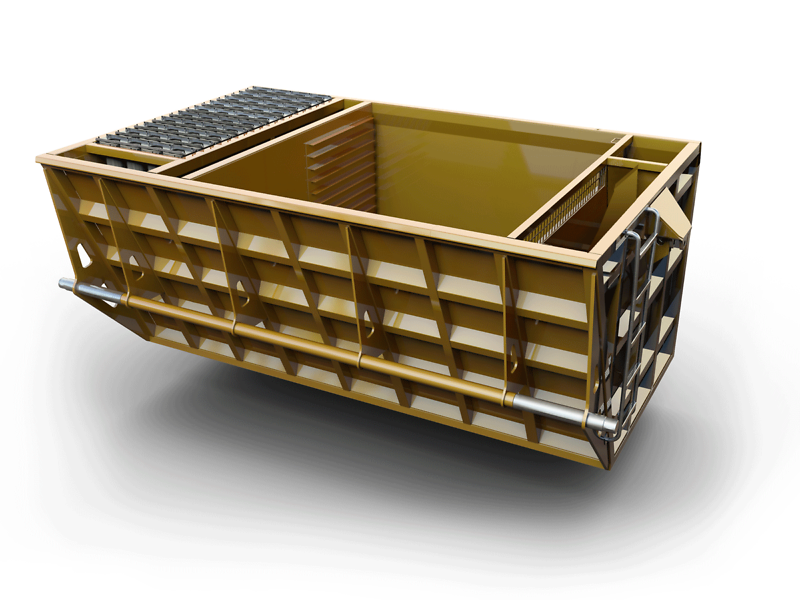

As part of the Government’s ongoing Rapid Cell Deployment Scheme, our works package included the foundations, drainage and services works to facilitate new modular prison cell units. Working in a prison environment with restricted access and shorter working days, was a logistical and time keeping challenge for the programme. Extensive works installing the drainage and services around already existing services were achieved using through specialist kit, our Vac Ex machine. Not only did this save on man hours and accessibility, but also enhanced safety measures.

- Works value: £2m

- Duration: 40 weeks

- Client: Galliford Try

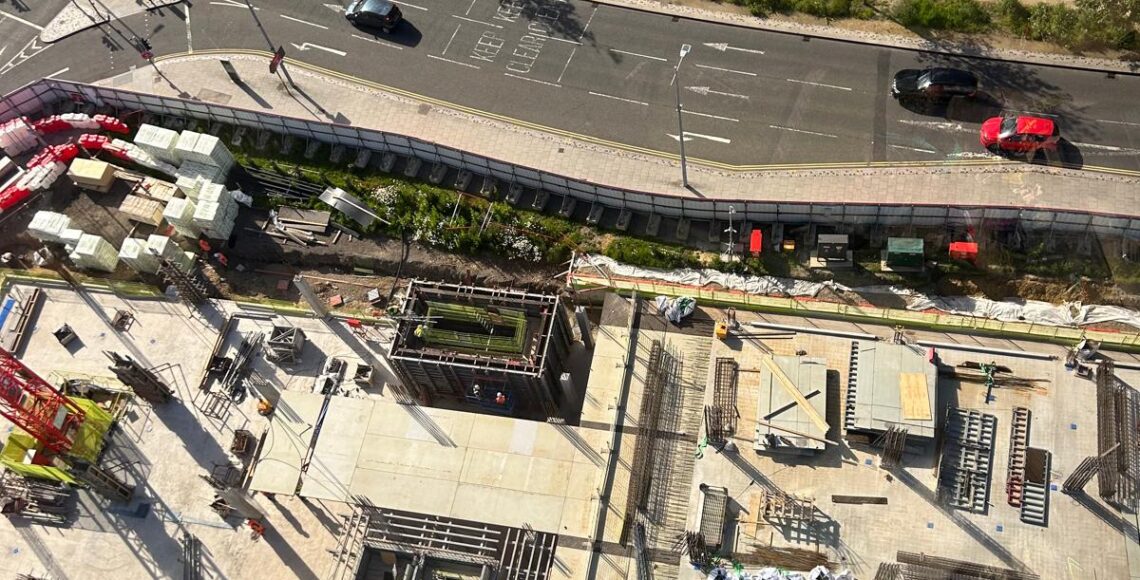

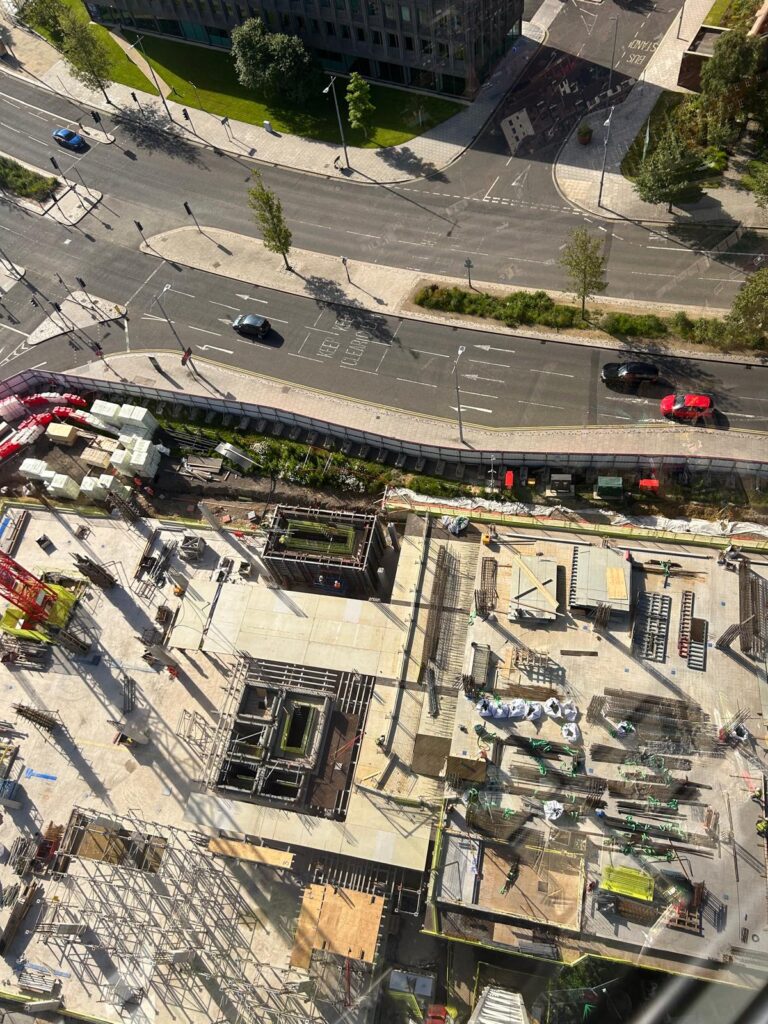

Sunderland Eye Infirmary

As part of the City’s ambitious Riverside masterplan, we are currently on site at the Sunderland Eye Infirmary with Kier Group. This is a four-storey concrete frame construction; inclusive of all new concrete foundations, ground floor slabs, upper floor slabs, columns, walls and lift / stair cores, including all associated below ground drainage and services works; plus a new associated Energy Centre compound including foundations, ground floor slabs, eternal yard slabs and associated below ground drainage & services works.

- Value: £9.7m

- Duration: 50 weeks

- Client: Kier Group

More updates to follow over the coming months.