The apprenticeship format works well for our business and for the students we take on. Real life work scenarios partnered with a wealth of experience from our teams help nurture and support their learning. The site working environment facilitates the acquisition of knowledge that a classroom is unable to offer.

We caught up with Cameron and Jack to hear how the last 12 months have rolled out since finishing their engineer apprenticeships.

Cameron – Level 4 Construction and Built Environment at York College: July 2021-23

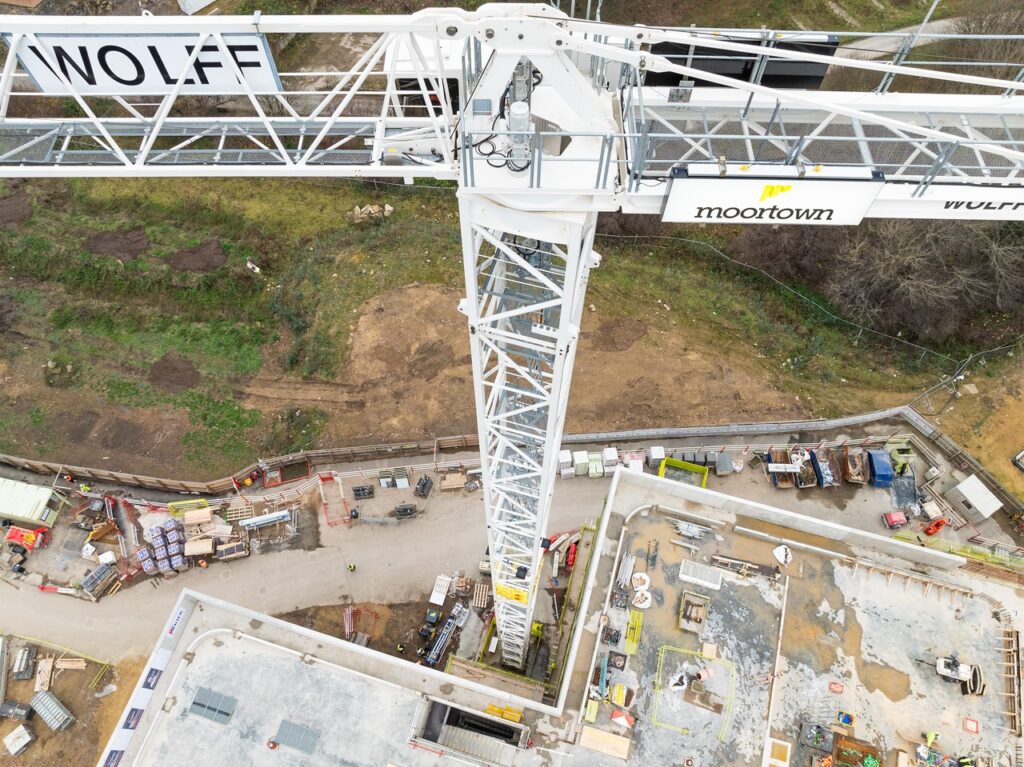

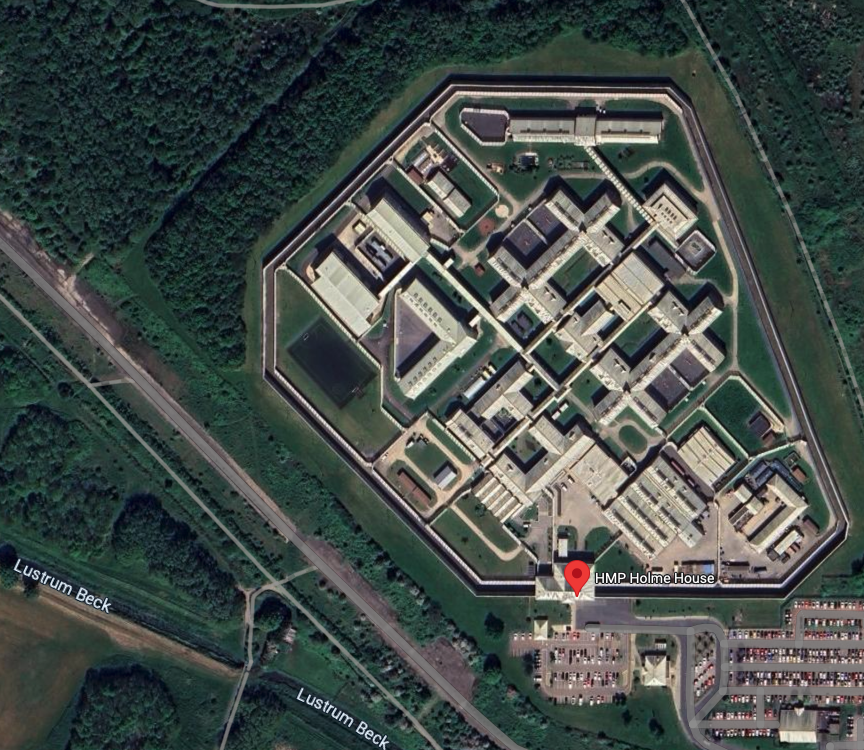

Since starting my apprenticeship with Moortown, I have worked on two large scale sites in the York area. Over the last 12 months, I have been based at a high security prison site called HMP Millsike where there is currently a huge extension being constructed. This project is set to be the UK’s first all-electric prison, and witnessing the scale of resources has been mind-blowing. With so much daily activity moving at a rapid pace, there’s never been a dull moment. Post apprenticeship, my continuation of learning and knowledge has grown so much more by remaining on a site which I first arrived on as an apprentice. Being surrounded by a collaborative hub of teams and a mixture of several sub-contractors and trades, has been incredibly insightful.

My role as an engineer has steadily expanded. Doing things such as setting out for bases, ducting and drainage around site and delegating work for others. I’ve become much more familiar with recording quality assurance and making sure things are done correctly to a high specification. These are just some examples that have helped me increase my confidence levels over the past year and gain a stronger sense of professional acumen.

It’s a personal highlight to see the progression of this project. When I first arrived at HMP Millsike, the site was a large empty space, and now, as I move onto my next site at Huddersfield University, it gives me much pride to see it move nearer to completion and to have been part of this project.

Jack – Level 3 Civil Engineer technician at Leeds College of Building: July 2021-23

I started my apprenticeship back in 2021 for a duration of two years, where I was initially based at a big Next Distribution Centre in South Elmsall for 18 months. Following this, I have been working on a mixture of sites and locations for varying lengths of time. This includes the HMP Millsike prison, Halifax Bus Station, Montagu Hospital in Mexborough, Parkgate Park & Ride in Rotherham and I’m now currently at the North Lindsey College in Scunthorpe.

All these projects have presented me with endless learning opportunities, working amongst different site teams and contractors. It has expanded my learning very quickly, and I have felt the benefit of increasing my responsibilities in the last 12 months, as it’s shaped and boosted my confidence levels.

On a daily basis, I am tasked with setting out on site, surveying the work done and sourcing the correct and latest drawings to ensure that everything is done to a high standard. A key moment for me which stands out is embracing more responsibility at the Mexborough hospital project, as this meant I was working independently for some of the time but also acquiring new skills and knowledge from others when setting out. Overall, this has really helped me to advance my engineering capabilities.

We are extremely proud to see our apprentices develop and thrive as they pave out their own route into their chosen career journey and establish a well-earned, qualified role. We invest a significant amount of our time and resources to finding students who have lots of potential and are passionate about a future in engineering in the construction industry.